Meropenem

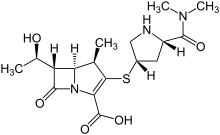

3-[5-(dimethylcarbamoyl) pyrrolidin-2-yl] sulfanyl-6- (1-hydroxyethyl)-4-methyl-7-oxo- 1-azabicyclo[3.2.0] hept-2-ene-2-carboxylic CAS 119478-56-7

Cubist Pharmaceuticals (CBST) reported good results from a late-stage trial of its new antibiotic Monday morning, sending Cubist stock gapping up 5.5% on the stock market today.

The trial compared ceftolozane/tazobactam, known in the industry as tol/taz, to meropenem (sold by AstraZeneca (AZN) as Monan or Meronem) in patients with complicated intra-abdominal infections (cIAI).

http://news.investors.com/technology/121613-683048-cbst-stock-up-on-toltaz-abdominal-trial.htm?ref%3DHPLNews

Meropenem is a broad-spectrum carbapenem antibiotic. It is active against Gram-positive and Gram-negative bacteria. Meropenem exerts its action by penetrating bacterial cells readily and interfering with the synthesis of vital cell wall components, which leads to cell death.

Meropenem is an ultra-broad spectrum injectable antibiotic used to treat a wide variety of infections. It is a beta-lactam and belongs to the subgroup of carbapenem, similar to imipenem and ertapenem. Meropenem was originally developed by Dainippon Sumitomo Pharma.[1][2] It gained US FDAapproval in July 1996. It penetrates well into many tissues and body fluids including the cerebrospinal fluid, bile, heart valves, lung, and peritonealfluid.[3] It is marketed in India by FHC with the brand name Merofit & outside India by AstraZeneca with the brand names Monan and Meronem.

Meropenem is bactericidal except against Listeria monocytogenes where it is bacteriostatic. It inhibits bacterial wall synthesis like other beta-lactamantibiotics. In contrast to other beta-lactams, it is highly resistant to degradation by beta-lactamases or cephalosporinases. Resistance generally arises due to mutations in penicillin binding proteins, production of metallo-beta-lactamases, or resistance to diffusion across the bacterial outer membrane.[4] Unlike imipenem, it is stable to dehydropeptidase-1 and can therefore be given without cilastatin

MERREM® I.V. (meropenem for injection) is a sterile, pyrogen-free, synthetic, broad-spectrum, carbapenem antibiotic for intravenous administration. It is (4R,5S,6S)-3-[[(3S,5S)-5- (Dimethylcarbamoyl)-3-pyrrolidinyl]thio]-6-[(1R)-1-hydroxyethyl]-4-methyl-7-oxo-1- azabicyclo[3.2.0]hept-2-ene-2-carboxylic acid trihydrate. Its empirical formula is C17H25N3O5S•3H2O with a molecular weight of 437.52. Its structural formula is:

|

MERREM I.V. (meropenem) is a white to pale yellow crystalline powder. The solution varies from colorless to yellow depending on the concentration. The pH of freshly constituted solutions is between 7.3 and 8.3. Meropenem is soluble in 5% monobasic potassium phosphate solution, sparingly soluble in water, very slightly soluble in hydrated ethanol, and practically insoluble in acetone or ether.

|

NMR

1H NMR(CDCl3, 400MHz) δ 5.5(1H), 5.20(2H), 4.75(1H), 4.26(2H), 3.4- 3.8(4H), 3.3(2H), 3.0(6H), 2.62(1H), 1.2∼ 1.3(8H)

The spectrum of action includes many Gram-positive and Gram-negative bacteria (including Pseudomonas) and anaerobic bacteria. The overall spectrum is similar to imipenem although meropenem is more active against Enterobacteriaceae and less active against Gram-positive bacteria. It is also very resistant to extended-spectrum beta lactamases but may be more susceptible to metallo-beta-lactamases.[3] Meropenem is frequently given in the treatment of febrile neutropenia. This condition frequently occurs in patients with hematological malignancies and cancer patients receiving anticancer drugs that cause bone marrow suppression. It is approved for complicated skin and skin structure infections, complicated intra-abdominal infections and bacterial meningitis.

Meropenem must be administered intravenously. It is supplied as a white crystalline powder to be dissolved in 5% monobasic potassium phosphate solution. Dosing must be adjusted for altered kidney function and for haemofiltration.[5]

The most common adverse effects are diarrhea (4.8%), nausea and vomiting (3.6%), injection-site inflammation (2.4%), headache (2.3%), rash (1.9%), and thrombophlebitis (0.9%).[4] Many of these adverse effects were observed in the setting of severely ill individuals who were already taking many medications including Vancomycin.[6][7] One study showed Clostridium difficile associated diarrhea (CDAD) happened in 3.6% of the patients on meropenem.[8] Meropenem also has a reduced potential for causing seizures in comparison with imipenem. Several cases of severe hypokalemia have been reported.[9][10]

To counter the tougher stuff, the front-line therapy against hospital-based E. coli infections has been the carbapenem antibiotics. These are extensions of the penicillin β-lactam motif, substituting sulfur for carbon, and are active against most strains of E. coli. Meropenem, first approved in 1996, was one of the first of this class, showing activity against abdominal and skin infections. Unlike penicillin, most carbapenems don’t reach the bloodstream efficiently when they are taken orally, which can limit their application. Though carbapenems may be strong antibiotics, E. coli fights back: in 2008, a bacterial enzyme was identified in E. coli taken from a patient traveling from India to Sweden, which granted resistance to the carbapenems. This enzyme, better known as NDM-1 (New Delhi metallo-beta-lactamase-1) has the power to cleave the β-lactam bond found in most penicillin-derived compounds, thus rendering them non-lethal to the bacterium. So far, the NDM-1 variant has been found in the US, Canada, Japan, Brazil, Afghanistan, Australia, the UK, and India. Thanks to horizontal gene transfer, where bacteria eject tiny fragments of their DNA for other bacteria to scoop up and incorporate into their own genes, scientists have found NDM-1 in multiple other species besides E. coli, including Salmonella and K. pneumoniae.

Other trade names include Meronir by Nirlife (India), Merowin by Strides Acrolab (India), PENMER by BIOCON (India), Aktimer by Aktimas Biopharmaceuticals (India), Zwipen, Carbonem, Ronem (Opsonin Pharma, BD) and Neomed (India), Mepem (Taiwan), Meropen (Japan, Korea),Merem (Australia) and Neopenem. [Merocon (Continental), Carnem (Laderly Biotech), Penro (Bosch), Meronem (ICI) {Pakistan}, Meroza (German Remedies),Merotrol (Lupin).

Administration of meropenem is indicated as single-agent therapy for the treatment of the following infections when caused by the following susceptible strains: complicated appendicitis and peritonitis caused by viridians group Streptococci, Escherichia coli, Klebsiella pneumoniae, Pseudomonas aeruginosa, Bacteroides fragilis, B. thetaiotaomicron, and Peptostreptococcus species; bacterial meningitis caused by Streptococcus pneumoniae, Haemophilus influenzae (b-lactamase and non-b-lactamase- producing strains), and Neisseria meningitidis. Meropenem has been found to be effective in eliminating concurrent bacteremia in association with bacterial meningitis.

ReferencesEdwards, JR; Turner, PJ; Wannop, C; Withnell, ES; Grindey, AJ; Nairn, K (1989 Feb). "In vitro antibacterial activity of SM-7338, a carbapenem antibiotic with stability to dehydropeptidase I". Antimicrobial agents and chemotherapy 33 (2): 215–22. doi:10.1128/AAC.33.2.215.PMC 171460. PMID 2655530.

- Creation of Meropen.

- ^ AHFS Drug Information (2006 ed.). American Society of Health-System Pharmacists. 2006.

- ^ a b Mosby's Drug Consult 2006 (16 ed.). Mosby, Inc. 2006.

- ^ Bilgrami, I; Roberts, JA; Wallis, SC; Thomas, J; Davis, J; Fowler, S; Goldrick, PB; Lipman, J (2010 Jul). "Meropenem dosing in critically ill patients with sepsis receiving high-volume continuous venovenous hemofiltration".Antimicrobial agents and chemotherapy 54 (7): 2974–8.doi:10.1128/AAC.01582-09. PMC 2897321.PMID 20479205.

- ^ Erden, M; Gulcan, E; Bilen, A; Bilen, Y; Uyanik, A; Keles, M (7 March 2013). "Pancytopenýa and Sepsýs due to Meropenem: A Case Report". Tropical Journal of Pharmaceutical Research 12 (1).doi:10.4314/tjpr.v12i1.21.

- ^ http://www.ehealthme.com/meropenem/meropenem-side-effects

(4R,5S,6S)-3-[[(3S,5S)-5-(dimethylcarbamoyl)-3-pyrrolidinyl]thio]-6-[(1R)-1-hydroxyethyl]-4-methyl-7-oxo-l-azabicyclo[3.2.0]hept-2-ene-2-carboxylic acid of Formula I, commonly known as meropenem, is a synthetic, broad-spectrum, carbapenem antibiotic.

Meropenem is commercially available as a trihydrate. Several processes for the preparation of meropenem and meropenem trihydrate are described in U.S. Pat. No. 4,888,344; WO Nos. 2006/035300; 2007/029084; 2007/104221; and 2005/118586.

Meropenem trihydrate is generally prepared by dissolving crude meropenem in water followed by cooling and adding a water miscible organic solvent such as acetone or isopropanol. This method requires heating of meropenem and water mixture to achieve complete dissolution and subsequent cooling of the solution along with the addition of water-miscible solvents, and optionally seed crystals, to maximize the precipitation or crystallization of meropenem trihydrate. The present inventors have observed that preparation of meropenem trihydrate from crude meropenem on a large scale results in a increased impurity content, specifically relating to meropenemic acid of Formula II and meropenem dimer of Formula III. The presence of impurities also impacts the yield.

The present inventors have not found that the problems associated with increased impurities, and the corresponding reduced yields, is due to the higher residence time in the batch mode reactors that are commonly employed during the scale-up. In batch mode reactors, the reaction is allowed to proceed for a specified time period after which the mixtures of unreacted materials and/or by-products, along with the desired end product, are withdrawn. After the reactants or starting materials are fed into the batch mode reactor, no further reactants or starting materials are added. The batch mode reactors have more residence time, especially during the heating and subsequent cooling steps. In the case ofmeropenem, the present inventors have observed that high residence time of meropenem, along with water, leads to decomposition of meropenem and increases impurity formation. On the other hand, the replacement of water with alternate organic solvents, for example, methanol, in which meropenem is freely soluble and does not require a heating step, results in higher residual solvent content.

U.S. Patent No. 4,888,344 provides a process for the preparation of the crystalline trihydrate of meropenem. U.S. Patent Nos. 4,943,569 and 5,122,604 provide similar processes for the preparation of meropenem trihydrate. Sunagawa et al., J. Antibiotics, XLIIL 1176 (1990) discusses several methods for preparation of carbapenem derivatives, specifically meropenem.

US Patent No. 4,943,569 discloses a method for obtaining amorphousmeropenem by coupling-reacting MAP with a side chain material as shown in Reaction Scheme 1 below to prepare meropenem-PNB whose carboxylic group is protected by p-methoxybenzyl group or p-nitrobenzyl group, dissolving it in an appropriate amount of a mixture solvent of tetrahydrofuran and ethanol, hydrogenating at room temperature for 3 hours in a buffer solution of morpholinopropanesulfonic acid in the presence of 10% palladium-carbon with 120% of weight ratio, filtering the catalyst, evaporating tetrahydrofuran and ethanol under vacuum, washing the residual solution with ethyl acetate, evaporating the solvent in an aqueous solution under vacuum, isolating by column chromatography using CHP-20P, and freeze-drying.

- [0004]In addition,

US Patent No. 4,888,344 introduces a method for obtainingmeropenem trihydrate by dissolving meropenem-PNB in a mixture solvent of tetrahydrofuran (THF) and water, adding 10% palladium-carbon thereto and reacting it under hydrogen atmosphere (4.8 atm) at room temperature for 5 hours, filtering the catalyst, evaporating tetrahydrofuran under vacuum, washing the residual solution with dichloromethane, evaporating the solvent in an aqueous solution under vacuum, concentrating by using reverse osmosis condensing apparatus and crystallizing. As compared with the method ofUS Patent No. 4,943,569 , since the method ofUS Patent No. 4,888,344 does not use a morpholinopropanesulfonic acid buffer solution and conducts the catalyzed hydrogenation reaction in a mixture solvent of water and tetrahydrofuran, it is advantageous that the hydrate can be obtained directly from the aqueous concentrated liquid without using the procedures of column chromatography, freeze-drying, isolation and recovery. - [0005]Furthermore, Korean Laid-open Patent Publication No.

1994-14399 improves the yield of the final target compound by introducing a novel process for synthesizing meropenem-PNB which can reduce the production procedures and carry out the production easily, as compared with a conventional method. However, since this method also employs the deprotection procedure of meropenem-PNB ofUS Patent No. 4,943,569 , a crystallization procedure is further conducted after obtaining meropenem in an amorphous form to obtain more stable trihydrate, resulting in meropenem trihydrate yield of 55.3% (deprotection reaction yield: 69.1%; crystallization yield: 80%).

One of the Pharma company truly dedicated to provide better solutions in the field of manufacturing medicines, innovative technologies and the ways to manage health, worldwide and are the best pharma manufacturer India..The Quality control system is an ongoing process which assures preventive efforts.It is one of the top meropenem manufacturer India and spectrums of research are carried out by the organization to upgrading formulation efficiency and improving drug delivery systems.

ReplyDelete